- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

ZZ-00020

Zhongzheng or as per your demand

3925900000

Concave FRP Grating

General Introduction

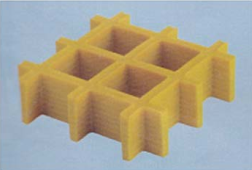

Glass fiber reinforced plastic (FRP) grating and glass fiber reinforced plastic plate, is a kind of glass fiber reinforced material, unsaturated polyester resin as matrix, through special processing and become a kind of plate material, with lots of blank space FRP gratings can be used as a structural material, used for the floor of the corrosion environment, trench cover, platform, ship deck, stair, catwalks, etc. With corrosion resistance and flame retardant, non - magnetic insulation, bright colors, a variety of styles and forms of alternative features.

Material Introduction

| Resin | |||||

| Resin Type | Resin Base | Description | Corrosion Resistance | Flame Spread Rating ASTM E 84 | Colors Available |

| VEFR225 | Vinyl ester | Superior corrosion resistance and retardant | Excellent | Class 1.25 or less | Dark gray, orange |

| IFR-25 | Vinyl ester | Industrial grade corrosion resistance and fire retardant | Very good | Class 1.10 or less | Dark, gray |

| IFR-10 | Isophthalic polyester | Industrial grade corrosion resistance and extra fire retardant | Very good | Class 1.25 or less | Custom |

| OFR-30 | Isophthalic polyester | Food grade corrosion resistance and fire retardant | Very good | Class 1.10 or less | Light gray, light green |

| OFR-25 | Ortho | Moderate corrosion resistance and fire retardant | Moderate | Class 1.25 or less | Green, yellow, light gray, dark gray |

| MP-5 | Phenolic resin | Low smoke and superior fire resistance | Very good | Class 1.25 or less | Reddish-brown, phenolic painting of the grating can be formed to obtain a gray or red finish |

| O-CR | Ortho | Moderate corrosion resistance | Moderate | No | Green, yellow, light gray, dark gray |

| Fiberglass Type | ||

| Code | Roving Type | Application Situation |

| E | E-glass roving | High strength and high corrosion resistance requirement. |

| C | C-glass roving | More economical than E-glass roving, has less strength, but better in acid resistance. |

| Filling | ||

| Code | Roving Type | Application Situation |

| ATH | Aluminum hydroxide | Flame retardant, smoke suppression, corrosion resistance situation |

| CAO | Calcium carbonate | More economical than ATH, suitable for no flame retardant requirement |

| PR | No filling | High corrosion resistance requirement situation |

Molded Grating Specifications

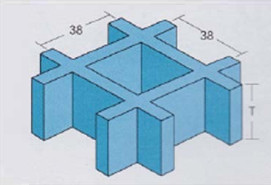

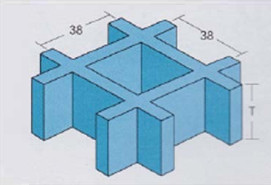

| 38*38 | ||||||

| Legend | Thickness (mm) | Bar Thickness (Top/Bottom) | Mesh Size (mm) | Panel Size Available(mm) | Weight (kg/m2) | Open Rate (%) |

| 13 | 6.0/5.0 | 38*38 | 1220*3660, 1220*4000, 1220*2440, 921*3055, 1264*4010 | 6.0 | 78 | |

| 14 | 6.0/5.0 | 38*38 | 1220*3660, 1220*4000, 1220*2440, 921*3055, 1264*4010 | 6.5 | 78 | |

| 15 | 6.0/5.0 | 38*38 | 1220*3660, 1220*4000, 1220*2440, 921*3055, 1264*4010 | 7.0 | 78 | |

| 20 | 6.0/5.0 | 38*38 | 1220*3660, 1220*4000, 1524*4010, 997*3012 | 9.8 | 65 | |

| 25 | 6.0/5.0 | 38*38 | 1220*3660, 1226*4010, 1530*4010, 921*3055, 1524*4010 | 12.3 | 68 | |

| 30 | 6.0/5.0 | 38*38 | 1220*3660, 1220*4010, 921*3055, 1524*4010 | 14.6 | 68 | |

| 38 | 7.0/5.0 | 38*38 | 1220*3660, 1220*4010, 2100*4240, 998*4010, 1220*2440, 921*3055, 1530*4010, 1530*3050, 1000*4000, 12226*3665 | 19.5 | 68 | |

| 50 | 9.5/7.5 Heavy duty | 38*38 | 1220*4010, 1220*3666,230*4010, 1220*2440, 921*3055 | 42 | 56 | |

| 60 | 10.5/8.5 Heavy duty | 38*38 | 1230*4010 | 50.4 | 54 | |

| 70 | 11.0/9.0 Heavy duty | 38*38 | 1230*4010 | 58.8 | 49 | |

| 40*40 | ||||||

| Legend | Thickness (mm) | Bar Thickness (Top/Bottom) | Mesh Size (mm) | Panel Size Available(mm) | Weight (kg/m2) | Open Rate (%) |

| 25 | 7.0/5.0 | 40*40 | 1007*3007, 1007*4007, 1247*4047, 1575*4047 | 12.3 | 67 | |

| 30 | 7.0/5.0 | 40*40 | 1527*4047, 1007*3007, 1247*4047 | 14.6 | 67 | |

| 38 | 7.0/5.0 | 40*40 | 1527*4047, 1247*4047, 1007*3007, 1007*4047 | 19.2 | 67 | |

| 40 | 7.0/5.0 | 40*40 | 1527*4047, 1007*3007, 1007*4047, 1247*4047 | 19.5 | 67 | |

| 50*50 | ||||||

| Legend | Thickness (mm) | Bar Thickness (Top/Bottom) | Mesh Size (mm) | Panel Size Available(mm) | Weight (kg/m2) | Open Rate (%) |

| 15 | 6.0/5.0 | 50*50 | 1228*4020, 1220*3660, 1220*2440 | 5.9 | 82 | |

| 40 | 6.8/5.0 | 50*50 | 1787*4530, 1225*4530 | 17.2 | 80 | |

| 25 | 7.0/5.0 | 50*50 | 1220*3660, 1226*4020, 1220*2440, 915*3050 | 11.5 | 78 | |

| 50 | 8.0/6.0 | 50*50 | 1524*4000, 1220*3660, 1220*2440, 1220*4000, 915*3050, 1532*4020 | 23.7 | 78 | |

| 83*83 | ||||||

| Legend | Thickness (mm) | Bar Thickness (Top/Bottom) | Mesh Size (mm) | Panel Size Available(mm) | Weight (kg/m2) | Open Rate (%) |

| 38 | 7.0/5.0 | 83*83 | 1007*4007, 1007*3007, 1007*4255 | 10.0 | 84 | |

| 40 | 7.0/5.0 | 83*83 | 1007*4007, 1007*3007, 1007*4255 | 11.0 | 84 | |

| 13*13/40*40 mirco mesh | ||||||

| Legend | Thickness (mm) | Bar Thickness (Top/Bottom) | Mesh Size (mm) | Panel Size Available(mm) | Weight (kg/m2) | Open Rate (%) |

| 25 | 6.0/4.5/5.0 | 13*13 40*40 | 1247*4047, 1007*3007, 1007*4047, 1530*4047 | 17.8 | 30 | |

| 30 | 6.0/4.5/5.0 | 13*13 40*40 | 1527*4047, 1247*4047, 1007*3007, 1007*4047 | 19.1 | 30 | |

| 38 | 6.0/4.5/5.0 | 13*13 40*40 | 1527*4047, 1247*4047, 1007*3007, 1007*4047 | 23.8 | 30 | |

| 25*50 | ||||||

| Legend | Thickness (mm) | Bar Thickness (Top/Bottom) | Mesh Size (mm) | Panel Size Available(mm) | Weight (kg/m2) | Open Rate (%) |

| 38 | 11.0/9.0 | 25*50 | 1220*1835 | 30.7 | 48 | |

| 50 | 12.0/9.0 | 25*50 | 1220*1835 | 41.8 | 48 | |

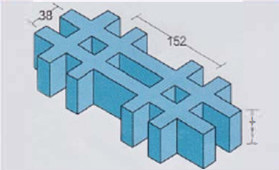

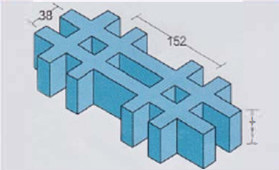

| 152*38 | ||||||

| Legend | Thickness (mm) | Bar Thickness (Top/Bottom) | Mesh Size (mm) | Panel Size Available(mm) | Weight (kg/m2) | Open Rate (%) |

| 38 | 8.0/6.0 | 152*38 | 1220*3660, 1220*2440, 915*3050 | 15.92 | 67 | |

| 38 | 15.0/8.0 | 152*38 | 1500*3660 | 19 | 62 | |

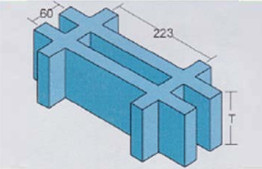

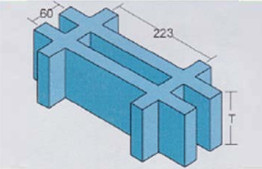

| 60*223 | ||||||

| Legend | Thickness (mm) | Bar Thickness (Top/Bottom) | Mesh Size (mm) | Panel Size Available(mm) | Weight (kg/m2) | Open Rate (%) |

| 40 | 6.3/6.5 | 60*223 | 1788*2238, 1788*4250 | 9.0 | 67 |

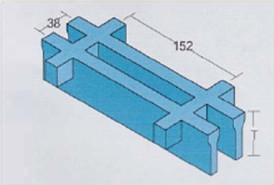

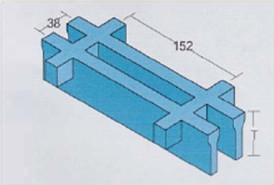

| 38*152 | ||||||

| Legend | Thickness (mm) | Bar Thickness (Top/Bottom) | Mesh Size (mm) | Panel Size Available(mm) | Weight (kg/m2) | Open Rate (%) |

| 38 stair treads | 7.0/5.0 | 38*152 | 580*3660, 580*4120 | 17 | 65 |

| 38*38 phenolic graiting | ||||||

| Legend | Thickness (mm) | Bar Thickness (Top/Bottom) | Mesh Size (mm) | Panel Size Available(mm) | Weight (kg/m2) | Open Rate (%) |

| 38 | 7.0/5.0 | 38*38 | 580*3660, 580*4120 | 19.5 | 65 |

| 38*152 phenolic graiting | ||||||

| Legend | Thickness (mm) | Bar Thickness (Top/Bottom) | Mesh Size (mm) | Panel Size Available(mm) | Weight (kg/m2) | Open Rate (%) |

| 38 (T-shape) | 15.0/8.0 | 38*152 | 1500*3660 | 19.0 | 62 |

Surfaces

|  |  |  |

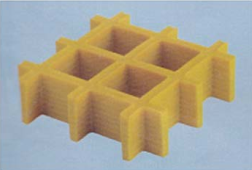

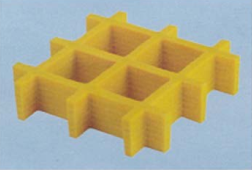

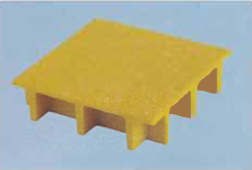

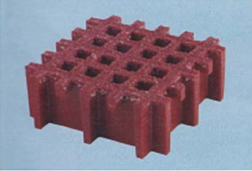

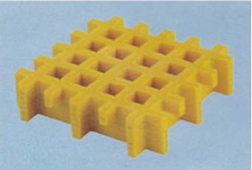

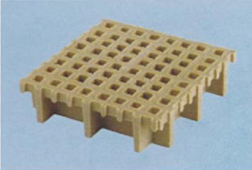

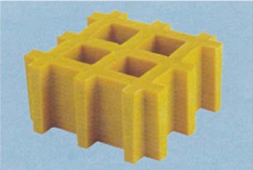

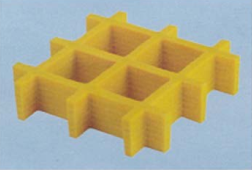

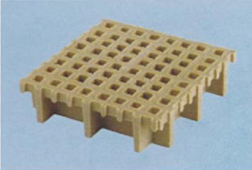

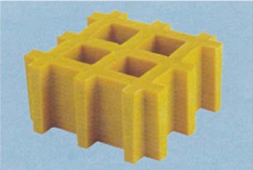

| Concave Surface | Smooth Surface | Solid cover-checker | Solid cover-gritted |

|  |  |  |

| Gritted Surface | Mini Mesh Surface | Macro Mesh Surface | Heavy Duty |

Application

Company Profile

Ningbo Zhongzheng steel grating Co. Ltd. is a professional enterprise in R & D., design, steel grating, SMC grating field. With innovative and pragmatic, scientific developing philosophy, following the criterion of ISO9001, it provides steel grating, stair tread, compound steel grating, fiberglass grating, drainage pit/trench cover, railing & stanchion, etc. It products are widely used in petroleum, chemical industry, environmental protection, power plants, pharmaceutical, printing and dyeing, brewing water supply and drainage, transportation and other industries.

With its ten years of professional management experience and production in press welding steel grating, it is one of the few enterprises who have the technology of flat steel and galvanized steel grating in the industry. The plentiful resources, skilled team, and high level of management, make it be the fastest developed, most potential grating products supplier.

Ningbo Zhongzheng steel grating Co., Ltd strictly followed the brand management of "quality making value, innovation leading the future", to provide clients high quality assurance, drawing, mechanics calculation, data collation service. With high-quality products and services combined, it has been well recognized by clients all over the world. The products have been exported to different countries and regions, such as South Korea, Singapore, Thailand, Australia, France, Kenya, etc.

WEBSITE: WWW.CNSTELLGRATING.COM

SALES DEPT. FOREIGN BUSINESS:

TEL.: 86-574 8388 8317

FAX: 86-574 8388 8317

ATTN.: Bruce

Concave FRP Grating

General Introduction

Glass fiber reinforced plastic (FRP) grating and glass fiber reinforced plastic plate, is a kind of glass fiber reinforced material, unsaturated polyester resin as matrix, through special processing and become a kind of plate material, with lots of blank space FRP gratings can be used as a structural material, used for the floor of the corrosion environment, trench cover, platform, ship deck, stair, catwalks, etc. With corrosion resistance and flame retardant, non - magnetic insulation, bright colors, a variety of styles and forms of alternative features.

Material Introduction

| Resin | |||||

| Resin Type | Resin Base | Description | Corrosion Resistance | Flame Spread Rating ASTM E 84 | Colors Available |

| VEFR225 | Vinyl ester | Superior corrosion resistance and retardant | Excellent | Class 1.25 or less | Dark gray, orange |

| IFR-25 | Vinyl ester | Industrial grade corrosion resistance and fire retardant | Very good | Class 1.10 or less | Dark, gray |

| IFR-10 | Isophthalic polyester | Industrial grade corrosion resistance and extra fire retardant | Very good | Class 1.25 or less | Custom |

| OFR-30 | Isophthalic polyester | Food grade corrosion resistance and fire retardant | Very good | Class 1.10 or less | Light gray, light green |

| OFR-25 | Ortho | Moderate corrosion resistance and fire retardant | Moderate | Class 1.25 or less | Green, yellow, light gray, dark gray |

| MP-5 | Phenolic resin | Low smoke and superior fire resistance | Very good | Class 1.25 or less | Reddish-brown, phenolic painting of the grating can be formed to obtain a gray or red finish |

| O-CR | Ortho | Moderate corrosion resistance | Moderate | No | Green, yellow, light gray, dark gray |

| Fiberglass Type | ||

| Code | Roving Type | Application Situation |

| E | E-glass roving | High strength and high corrosion resistance requirement. |

| C | C-glass roving | More economical than E-glass roving, has less strength, but better in acid resistance. |

| Filling | ||

| Code | Roving Type | Application Situation |

| ATH | Aluminum hydroxide | Flame retardant, smoke suppression, corrosion resistance situation |

| CAO | Calcium carbonate | More economical than ATH, suitable for no flame retardant requirement |

| PR | No filling | High corrosion resistance requirement situation |

Molded Grating Specifications

| 38*38 | ||||||

| Legend | Thickness (mm) | Bar Thickness (Top/Bottom) | Mesh Size (mm) | Panel Size Available(mm) | Weight (kg/m2) | Open Rate (%) |

| 13 | 6.0/5.0 | 38*38 | 1220*3660, 1220*4000, 1220*2440, 921*3055, 1264*4010 | 6.0 | 78 | |

| 14 | 6.0/5.0 | 38*38 | 1220*3660, 1220*4000, 1220*2440, 921*3055, 1264*4010 | 6.5 | 78 | |

| 15 | 6.0/5.0 | 38*38 | 1220*3660, 1220*4000, 1220*2440, 921*3055, 1264*4010 | 7.0 | 78 | |

| 20 | 6.0/5.0 | 38*38 | 1220*3660, 1220*4000, 1524*4010, 997*3012 | 9.8 | 65 | |

| 25 | 6.0/5.0 | 38*38 | 1220*3660, 1226*4010, 1530*4010, 921*3055, 1524*4010 | 12.3 | 68 | |

| 30 | 6.0/5.0 | 38*38 | 1220*3660, 1220*4010, 921*3055, 1524*4010 | 14.6 | 68 | |

| 38 | 7.0/5.0 | 38*38 | 1220*3660, 1220*4010, 2100*4240, 998*4010, 1220*2440, 921*3055, 1530*4010, 1530*3050, 1000*4000, 12226*3665 | 19.5 | 68 | |

| 50 | 9.5/7.5 Heavy duty | 38*38 | 1220*4010, 1220*3666,230*4010, 1220*2440, 921*3055 | 42 | 56 | |

| 60 | 10.5/8.5 Heavy duty | 38*38 | 1230*4010 | 50.4 | 54 | |

| 70 | 11.0/9.0 Heavy duty | 38*38 | 1230*4010 | 58.8 | 49 | |

| 40*40 | ||||||

| Legend | Thickness (mm) | Bar Thickness (Top/Bottom) | Mesh Size (mm) | Panel Size Available(mm) | Weight (kg/m2) | Open Rate (%) |

| 25 | 7.0/5.0 | 40*40 | 1007*3007, 1007*4007, 1247*4047, 1575*4047 | 12.3 | 67 | |

| 30 | 7.0/5.0 | 40*40 | 1527*4047, 1007*3007, 1247*4047 | 14.6 | 67 | |

| 38 | 7.0/5.0 | 40*40 | 1527*4047, 1247*4047, 1007*3007, 1007*4047 | 19.2 | 67 | |

| 40 | 7.0/5.0 | 40*40 | 1527*4047, 1007*3007, 1007*4047, 1247*4047 | 19.5 | 67 | |

| 50*50 | ||||||

| Legend | Thickness (mm) | Bar Thickness (Top/Bottom) | Mesh Size (mm) | Panel Size Available(mm) | Weight (kg/m2) | Open Rate (%) |

| 15 | 6.0/5.0 | 50*50 | 1228*4020, 1220*3660, 1220*2440 | 5.9 | 82 | |

| 40 | 6.8/5.0 | 50*50 | 1787*4530, 1225*4530 | 17.2 | 80 | |

| 25 | 7.0/5.0 | 50*50 | 1220*3660, 1226*4020, 1220*2440, 915*3050 | 11.5 | 78 | |

| 50 | 8.0/6.0 | 50*50 | 1524*4000, 1220*3660, 1220*2440, 1220*4000, 915*3050, 1532*4020 | 23.7 | 78 | |

| 83*83 | ||||||

| Legend | Thickness (mm) | Bar Thickness (Top/Bottom) | Mesh Size (mm) | Panel Size Available(mm) | Weight (kg/m2) | Open Rate (%) |

| 38 | 7.0/5.0 | 83*83 | 1007*4007, 1007*3007, 1007*4255 | 10.0 | 84 | |

| 40 | 7.0/5.0 | 83*83 | 1007*4007, 1007*3007, 1007*4255 | 11.0 | 84 | |

| 13*13/40*40 mirco mesh | ||||||

| Legend | Thickness (mm) | Bar Thickness (Top/Bottom) | Mesh Size (mm) | Panel Size Available(mm) | Weight (kg/m2) | Open Rate (%) |

| 25 | 6.0/4.5/5.0 | 13*13 40*40 | 1247*4047, 1007*3007, 1007*4047, 1530*4047 | 17.8 | 30 | |

| 30 | 6.0/4.5/5.0 | 13*13 40*40 | 1527*4047, 1247*4047, 1007*3007, 1007*4047 | 19.1 | 30 | |

| 38 | 6.0/4.5/5.0 | 13*13 40*40 | 1527*4047, 1247*4047, 1007*3007, 1007*4047 | 23.8 | 30 | |

| 25*50 | ||||||

| Legend | Thickness (mm) | Bar Thickness (Top/Bottom) | Mesh Size (mm) | Panel Size Available(mm) | Weight (kg/m2) | Open Rate (%) |

| 38 | 11.0/9.0 | 25*50 | 1220*1835 | 30.7 | 48 | |

| 50 | 12.0/9.0 | 25*50 | 1220*1835 | 41.8 | 48 | |

| 152*38 | ||||||

| Legend | Thickness (mm) | Bar Thickness (Top/Bottom) | Mesh Size (mm) | Panel Size Available(mm) | Weight (kg/m2) | Open Rate (%) |

| 38 | 8.0/6.0 | 152*38 | 1220*3660, 1220*2440, 915*3050 | 15.92 | 67 | |

| 38 | 15.0/8.0 | 152*38 | 1500*3660 | 19 | 62 | |

| 60*223 | ||||||

| Legend | Thickness (mm) | Bar Thickness (Top/Bottom) | Mesh Size (mm) | Panel Size Available(mm) | Weight (kg/m2) | Open Rate (%) |

| 40 | 6.3/6.5 | 60*223 | 1788*2238, 1788*4250 | 9.0 | 67 |

| 38*152 | ||||||

| Legend | Thickness (mm) | Bar Thickness (Top/Bottom) | Mesh Size (mm) | Panel Size Available(mm) | Weight (kg/m2) | Open Rate (%) |

| 38 stair treads | 7.0/5.0 | 38*152 | 580*3660, 580*4120 | 17 | 65 |

| 38*38 phenolic graiting | ||||||

| Legend | Thickness (mm) | Bar Thickness (Top/Bottom) | Mesh Size (mm) | Panel Size Available(mm) | Weight (kg/m2) | Open Rate (%) |

| 38 | 7.0/5.0 | 38*38 | 580*3660, 580*4120 | 19.5 | 65 |

| 38*152 phenolic graiting | ||||||

| Legend | Thickness (mm) | Bar Thickness (Top/Bottom) | Mesh Size (mm) | Panel Size Available(mm) | Weight (kg/m2) | Open Rate (%) |

| 38 (T-shape) | 15.0/8.0 | 38*152 | 1500*3660 | 19.0 | 62 |

Surfaces

|  |  |  |

| Concave Surface | Smooth Surface | Solid cover-checker | Solid cover-gritted |

|  |  |  |

| Gritted Surface | Mini Mesh Surface | Macro Mesh Surface | Heavy Duty |

Application

Company Profile

Ningbo Zhongzheng steel grating Co. Ltd. is a professional enterprise in R & D., design, steel grating, SMC grating field. With innovative and pragmatic, scientific developing philosophy, following the criterion of ISO9001, it provides steel grating, stair tread, compound steel grating, fiberglass grating, drainage pit/trench cover, railing & stanchion, etc. It products are widely used in petroleum, chemical industry, environmental protection, power plants, pharmaceutical, printing and dyeing, brewing water supply and drainage, transportation and other industries.

With its ten years of professional management experience and production in press welding steel grating, it is one of the few enterprises who have the technology of flat steel and galvanized steel grating in the industry. The plentiful resources, skilled team, and high level of management, make it be the fastest developed, most potential grating products supplier.

Ningbo Zhongzheng steel grating Co., Ltd strictly followed the brand management of "quality making value, innovation leading the future", to provide clients high quality assurance, drawing, mechanics calculation, data collation service. With high-quality products and services combined, it has been well recognized by clients all over the world. The products have been exported to different countries and regions, such as South Korea, Singapore, Thailand, Australia, France, Kenya, etc.

WEBSITE: WWW.CNSTELLGRATING.COM

SALES DEPT. FOREIGN BUSINESS:

TEL.: 86-574 8388 8317

FAX: 86-574 8388 8317

ATTN.: Bruce